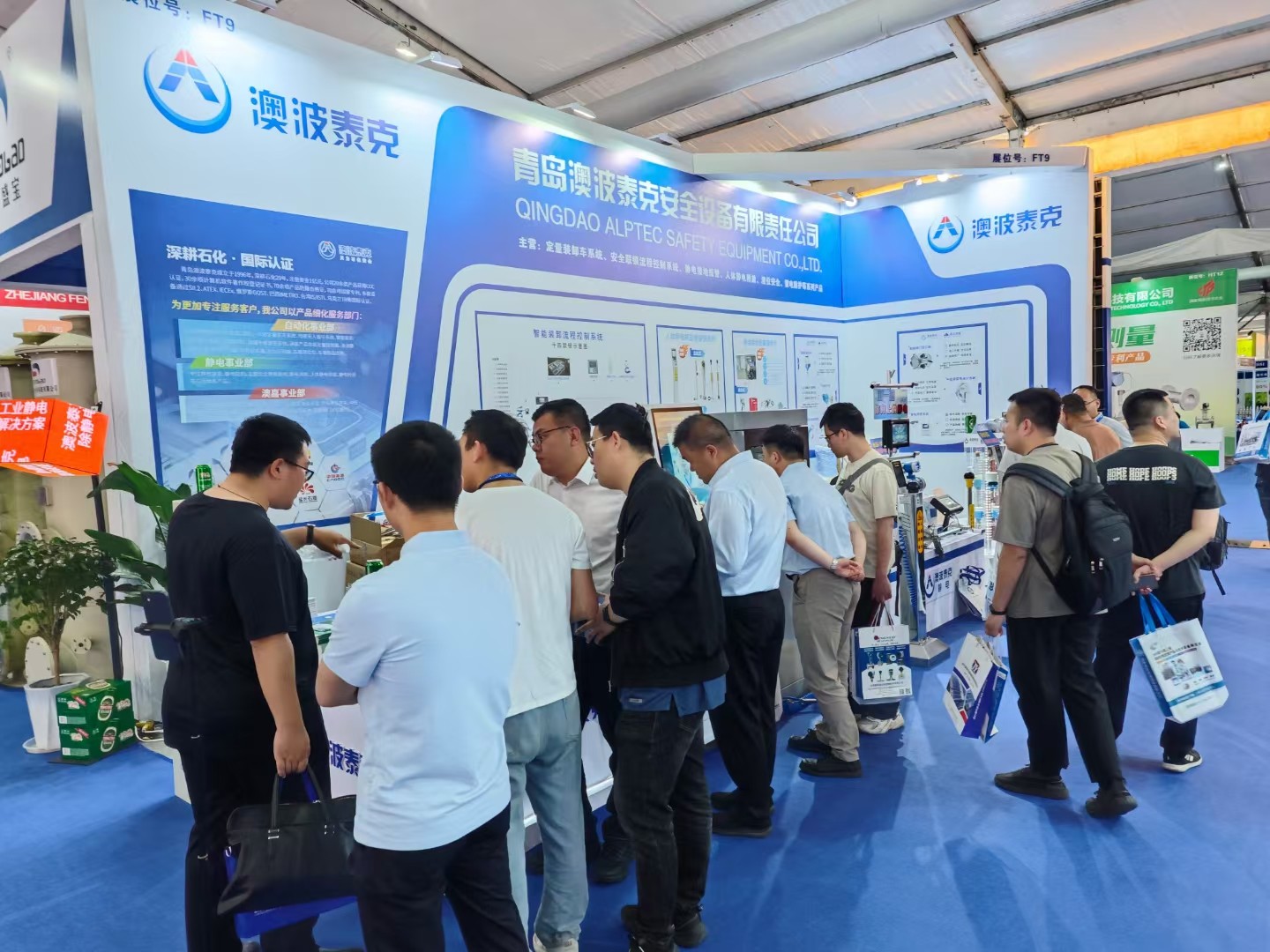

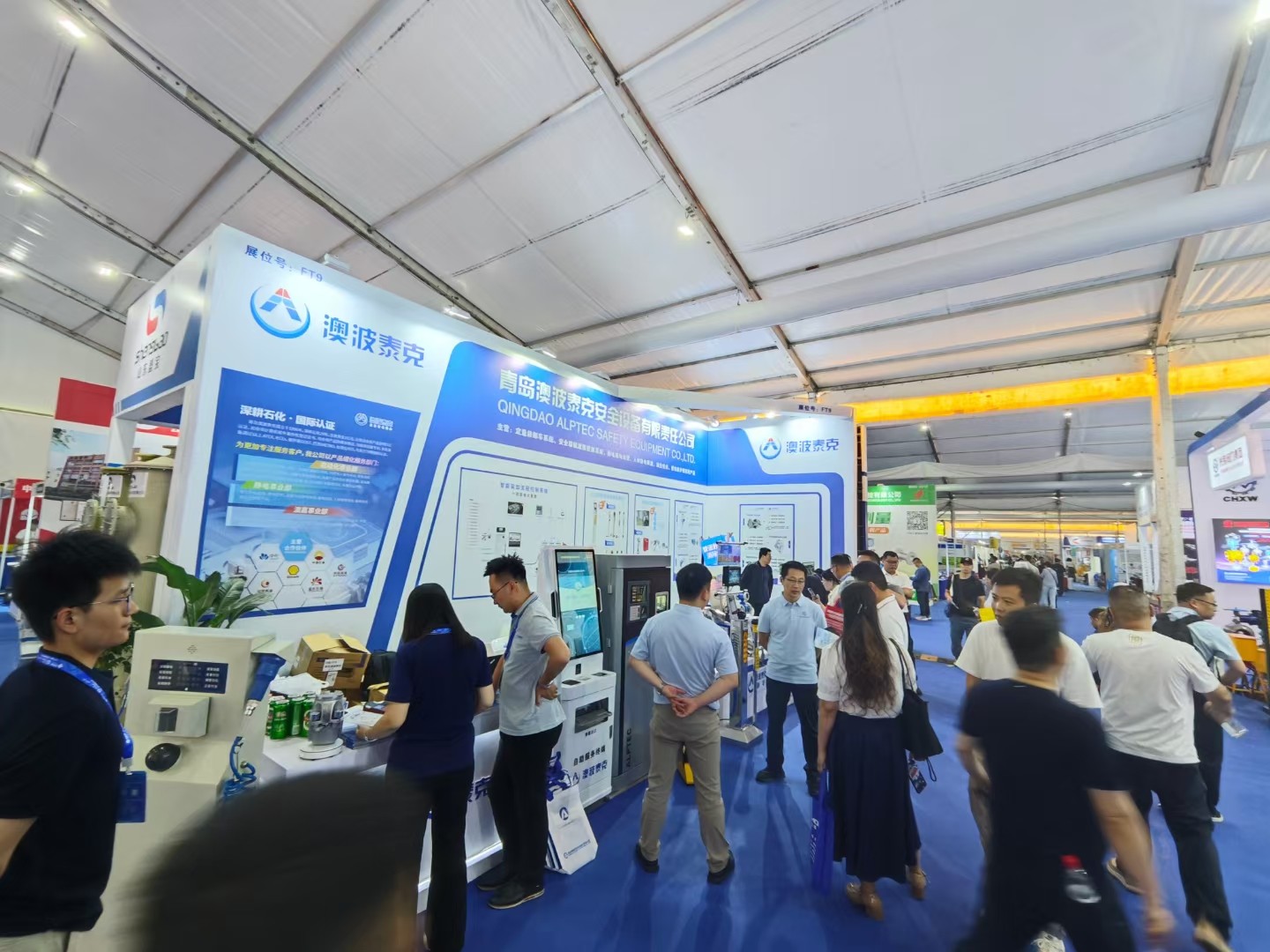

Static Grounding System are showed on China Chemical Teconology and Equipment Exhibition

Static Grounding System are showed on China Chemical Teconology and Equipment Exhibition 2025

Personal Electrostatic Discharge Devices

Batch Controllers

Mass Flow Meters

Static Electricity Elimination in the Human Body

https://www.staticgrounding.cn/pid18286585/Personal-Electrostatic-Eliminating-System-provided-by-china-manufacture.htm

Static electricity buildup in the human body is a common phenomenon, especially in dry environments or when wearing synthetic fabrics. This accumulation can reach voltages up to 35,000 volts, causing uncomfortable shocks and potential damage to sensitive electronic devices. Understanding effective static elimination methods is crucial for personal comfort and workplace safety.

There are several practical ways to discharge body static safely. The most effective method involves touching grounded metal objects frequently, which allows gradual charge dissipation. Wearing natural fiber clothing (cotton or wool) significantly reduces static generation compared to synthetic materials. Anti-static wrist straps are essential for professionals working with electronics, providing continuous grounding. Humidifiers maintain optimal 40-60% humidity levels, preventing excessive charge buildup. Special conductive floor mats and footwear are used in electronics manufacturing areas. Applying moisturizer keeps skin hydrated, reducing its insulating properties.

Regular hand washing with water also helps neutralize charges temporarily. For immediate discharge, the "coin trick" - touching a metal surface with a coin first - minimizes shock sensation. In industrial settings, ionizing blowers neutralize static on personnel before entering sensitive areas. These methods are particularly important in hospitals (protecting equipment), manufacturing (preventing product damage), and fuel handling (avoiding ignition risks).

Proper static control improves daily comfort and prevents catastrophic incidents in sensitive environments. By combining environmental controls with personal discharge habits, static-related problems can be effectively managed.

Batch Controllers: Precision in Industrial Measurement

https://www.staticgrounding.cn/pid18437345/One-line-Batch-Controller-System.htm

Batch controllers are essential automation devices used across industries to accurately measure and control material quantities during production processes. These intelligent instruments combine flow measurement with programmable logic to ensure precise batching operations in applications ranging from petroleum refueling to food production.

Modern batch controllers integrate three core components: a flow sensor (measuring liquid or gas volume), a control valve (regulating material flow), and a microprocessor (managing the batching sequence). Advanced models feature touchscreen interfaces, multiple preset recipes, and communication protocols like Modbus for system integration. Their typical accuracy reaches ±0.1% with proper calibration.

Key industries utilizing batch controllers include:

Oil & gas - for loading tankers with exact fuel quantities

Chemical processing - ensuring precise additive mixtures

Food/beverage - maintaining recipe consistency

Pharmaceutical - meeting strict dosage requirements

Operational advantages include automated shutdown at preset quantities, leak detection capabilities, and comprehensive data logging for quality control. Safety features like overfill prevention are critical for hazardous materials. When selecting batch controllers, engineers consider material viscosity, flow rate ranges, and environmental conditions.

The latest innovations incorporate IoT connectivity for remote monitoring and predictive maintenance alerts. As industrial automation advances, batch controllers continue evolving with enhanced algorithms for faster cut-off responses and improved measurement compensation techniques, solidifying their role as indispensable tools for modern manufacturing precision.

Coriolis Mass Flow Meters

https://www.staticgrounding.cn/pid18288222/high-precision-Coriolis-Mass-Flow-Meter-with-316L-stainless-steel.htm: Precision Measurement Technology

Coriolis mass flow meters represent the gold standard in fluid measurement technology, utilizing the Coriolis effect principle to directly measure mass flow rate with exceptional accuracy. These sophisticated instruments measure both mass flow and density simultaneously, making them indispensable in industries requiring precise process control.

The operational principle relies on vibrating tubes through which fluid flows. As fluid moves through the oscillating tubes, it generates measurable phase shifts proportional to mass flow due to the Coriolis effect. Key advantages include:

Direct mass measurement (unaffected by temperature/pressure changes)

Typical accuracy of ±0.1% of reading

Multi-parameter output (mass flow, density, temperature)

Minimal maintenance with no moving parts

Industrial applications span petroleum refining (custody transfer), chemical processing (reactor feed control), food production (ingredient batching), and pharmaceutical manufacturing (precise dosing). Modern designs feature compact configurations, reduced pressure drop, and advanced diagnostics.

Recent technological advancements incorporate digital signal processing for improved noise rejection and smart communication protocols (HART, Foundation Fieldbus) for Industry 4.0 integration. While initial costs exceed volumetric flow meters, their long-term reliability and reduced calibration needs provide superior lifecycle value.

When selecting Coriolis meters, engineers consider fluid characteristics, pipe size, and process conditions. Proper installation following manufacturer guidelines prevents measurement errors from external vibrations. As process industries demand higher precision, Coriolis technology continues evolving with enhanced materials and self-verification capabilities, maintaining its position as the most accurate flow measurement solution available today.